Flexible and scalable 3PL fulfilment is key

Labour shortages, scarce and expensive real estate and surging volumes are some of the challenges 3PLs face. Traditional automation solutions lack the flexibility and scalability to cope with unpredictable business volumes, resulting in inefficient order fulfilment.

Flexible and scalable warehouse automation solutions have become critical for companies to adapt to fast-changing business environments, increasing operational efficiency and meeting customers' rising expectations.

What are we trying to solve?

Top 3PL challenges

Labour shortage

Lack of available real estate

Low flexibility

Low scalability during peaks

Low operational efficiency

Meeting your customer's expectations

Hai Robotics is helping 3PL companies to meet their customers' demands by providing highly flexible and scalable warehouse automation solutions to ensure optimal performance and meet customers' expectations.

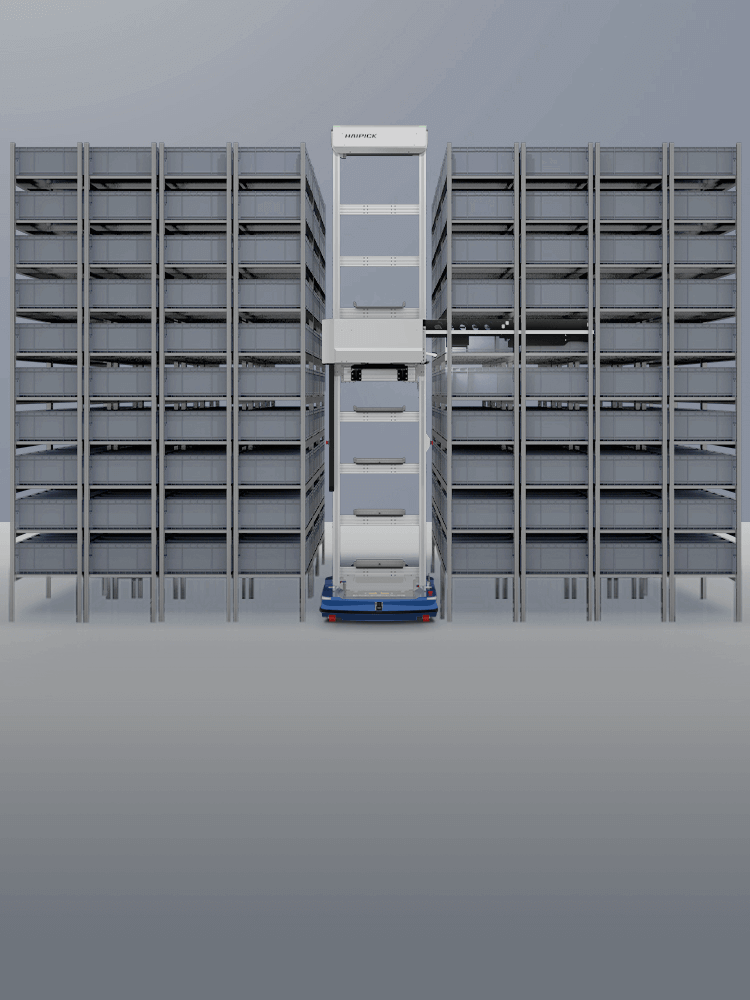

3PL warehouse solution

3PL warehouse solution

400% more storage

Utilise available vertical space and increase storage density by 80%-400%.

Flexible handling

Handle different product types and load carriers (cartons, totes, non-cubic items).

Scale up/down

Handle sudden surges in volumes with our 3PL dedicated peak rental program.

Improved efficiency

Reduce dependency on a large workforce.

Fast deployment

Deploy within 6 months after contract signature.

Financial flexibility

Choose between CAPEX or OPEX via leasing.

SF-DHL Supply Chain

Apparel Warehouse

20 times

inbound efficiency Improved

7 days

complete deployment

160%

storage density

With Hai Robotics' solution, the company transformed and improved overall operation efficiency, reduced labour costs, and optimized storage density.

Winit

Cross-border E-commerce Warehouse

50,000

daily processed pieces

99.99%

picking accuracy

3-4 times

improved warehouse efficiency

Winit needed to improve its warehouse operational efficiency and reduce costs. Hai Robotics' solution has been applied in the e-commerce industry, providing a mature and stable solution to meet Winit's requirements.

Maersk Contract Logistics

Apparel Warehouse

63,770

storage locations within 7,500㎡

1,104

outbound cases per hour

99.99%

picking accuracy

Maersk Contract Logistics provides third-party logistics services to famous casual wear companies. Its distribution centre handles B2B and B2C picking and delivery. Hai Robotics provided high picking efficiency and storage density, meeting the high outbound efficiency requirements to fulfil the orders.

Maersk Contract Logistics provides third-party logistics services to famous casual wear companies. Its distribution centre handles B2B and B2C picking and delivery. Hai Robotics provided high picking efficiency and storage density, meeting the high outbound efficiency requirements to fulfil the orders.

Large Online Retailer

Cross-border E-commerce Warehouse

42,000

storage locations

1,500

cases/hour system picking efficiency

99.99%

picking accuracy

The company mainly engages in cross-border e-commerce. After a successful first project using the HaiPick system, the company decided to implement the solution to power their first semi-automated warehouse in Lutterworth, UK. The equipment included CE-certified HaiPick robots and conveyors.